THE TOPIC

You’ve been given a new design project, yay! The client doesn’t know a lot about sustainable design, but they don’t want to do the standard thing, they want to do something better. They are even thinking Passive House could be an option!

You get out your pencil and start working through the design. What are the first steps toward a sustainable design? Maybe you consider solar orientation first, or proximity to natural features like creeks or forested areas. If you’re like me one of my initial reactions is - INSULATE MORE! It’s one of the best ways to reduce energy use and it’s even the first principle of Passive House. What could be wrong with that?

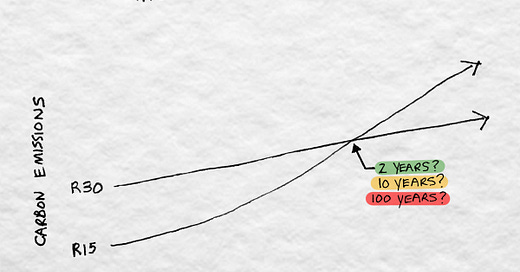

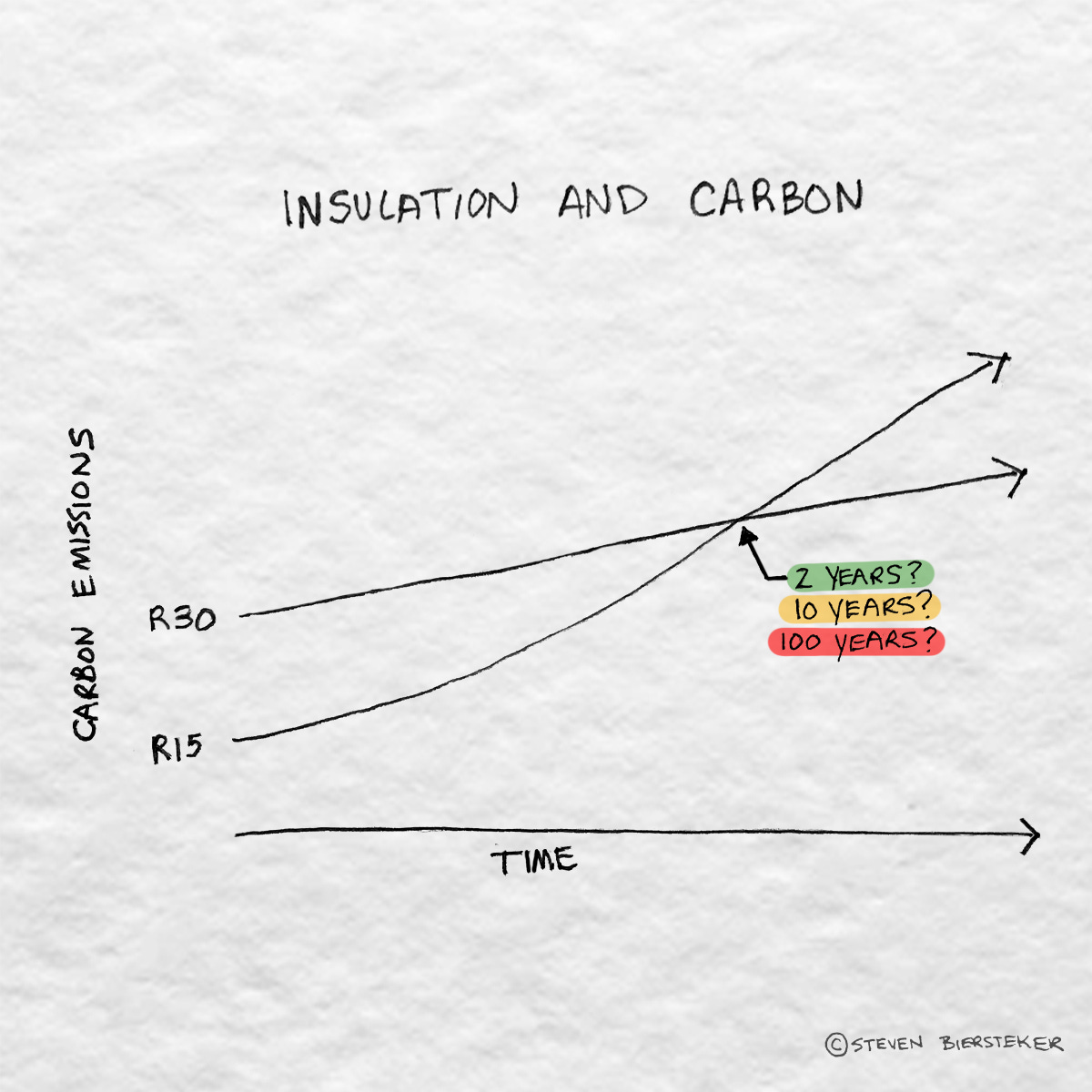

The simple problem with super-insulating is upfront carbon. Insulation reduces the amount of energy (and by virtue carbon) over the long-term use of a building. But the production of the insulation requires carbon that is released before the building is even built! This makes every inch of insulation a fine balance between how much it saves in the long run vs how much additional upfront carbon it causes now.

“I used to think more insulation was always the sustainable option. Now I realize the issue is much more complex and there isn’t one answer.”

THE GRAPHIC

We need to be looking at carbon emissions over time, not just energy use. So how much insulation is best? It depends on your energy grid, the type of insulation, and the mechanical systems you are using. Is that payback 2 years, 10 years, or 100 years?

WHY IT MATTERS

The amount and type of insulation matters for three primary reasons:

Upfront carbon is as important as operational carbon

The insulation type and thickness have significant carbon impacts

Whole-Life-Carbon is the metric that matters

Let’s dig a little deeper:

1 - Upfront carbon is as important as operational carbon

I’ve written a few times about the importance of considering both embodied and operational carbon in design projects. However, my perspective is quickly shifting as I see the impact that embodied carbon has on overall carbon emissions.

This issue is exasperated by the fact that carbon emissions are generally not regulated in architecture. Energy is generally controlled through Building Codes, but even this misses the more important factor of GHG emissions related to energy use.

Embodied carbon however is virtually unregulated and mostly undocumented and stands as a bigger problem that needs resolution.

2 - Insulation type and thickness make big impacts

When considering which insulation to choose, type and thickness have the biggest impact on both r-value and carbon impact. The somewhat obvious one is r-value. Choose a material with a higher U-Value and increase thickness and you will reduce your building energy use. Carbon is similar. Materials with higher carbon intensities and thicker amounts result in higher total carbon.

I’m not going to go over the different types of insulation and their impacts on the project. For that, you can read any of the guides and reports below.

The lesson here is to be careful what type of insulation you choose. Insulating more isn’t always the most sustainable solution.

3 - Whole life-cycle carbon is the metric that matters

Upfront carbon & operational carbon are only a part of the larger equation. What we really need to be looking at is the whole-life carbon impact of our decisions. This requires that both Energy Models and Life Cycle Assessments should be done your projects. Any energy model will give you the operational carbon over the project lifecycle, and the Life Cycle Assessment will inform you on the impact of each aspect on the overall project.

1 TIP - HOW TO REDUCE

The principle is simple, although it depends on where your building is. First focus on making sure there are no HFC gasses in any materials. HFC & HFO are blowing agents used in spray foam and XPS insulations that have very different impacts on the environment.

If you live in a country like Canada where HFC gasses are banned (yay!) then focus on reducing XPS altogether.

Even the best XPS insulations have more impact than most other types.

1 RESOURCE - TO HELP YOU ACT

There are so many fantastic resources on this topic. Seriously - if you haven’t read up on this topic, you need to. It’s critical to designing sustainable buildings.

Embodied Carbon Values in Insulation - KPMB Study

Reduce Whole Life Carbon - Mantel Developments

I NEED YOUR HELP!

What do you get the most value out of?

Suppose you are ignoring the reduction in mechanical system capacity and the resulting refrigerant reduction that comes from an improved thermal enclosure. In that case, you are also guilty of not looking at the "whole picture." The smaller and simpler mechanical systems that high-performance enclosures allow (along with the enclosure design/installation quality control that gives engineers the confidence to size equipment aggressively/accurately) can have a much bigger impact on the life cycle emissions of a project than the insulation type.

Any discussion of building emissions without a discussion of refrigerant emissions will leave a lot of emissions reduction on the table.

If realistic operational emissions factors are utilized, operational emissions rapidly dwarf enclosure upgrades in nearly every case. Do the math.

I have discussed this in more depth here: https://www.youtube.com/watch?v=vL9OxJbN3dc

Furthermore, building projects to Passive House levels of airtightness or even tighter (many projects consistently test 50% lower than PH leakage targets) can cut a great deal of insulation out of their projects while achieving the same levels of overall thermal performance. CI thickness can often be cut in half.

I'd be happy to assist you with running one of your projects through a simple upfront and operational carbon emissions tool I have developed with the Passive House Accelerator that quickly assesses building emissions including insulation materials, glazing, mechanicals, renewables, storage, and forward looking emissions out to 2050 using NREL Cambium datasets. I think you might be surprised with the results.