CA12 - BREAKING THE BRIDGE

Why thermal bridging will cause long-term pain.

Before we get into this week’s topic I want to give you all a big THANK YOU for all the input I received last week. I feel like I know ya’ll a bit better and can help solve your problems. If you have anything specific I can help you with - send me an email. I’m all ears.

THE TOPIC - THERMAL BRIDGING

Let’s talk about energy loss. Energy can pass through the envelope in a number of ways. I’m not going to go into scientific detail here, but the basics are convection, conduction, & radiation. Today’s topic will focus on conduction, the transfer of energy from materials directly in contact with each other.

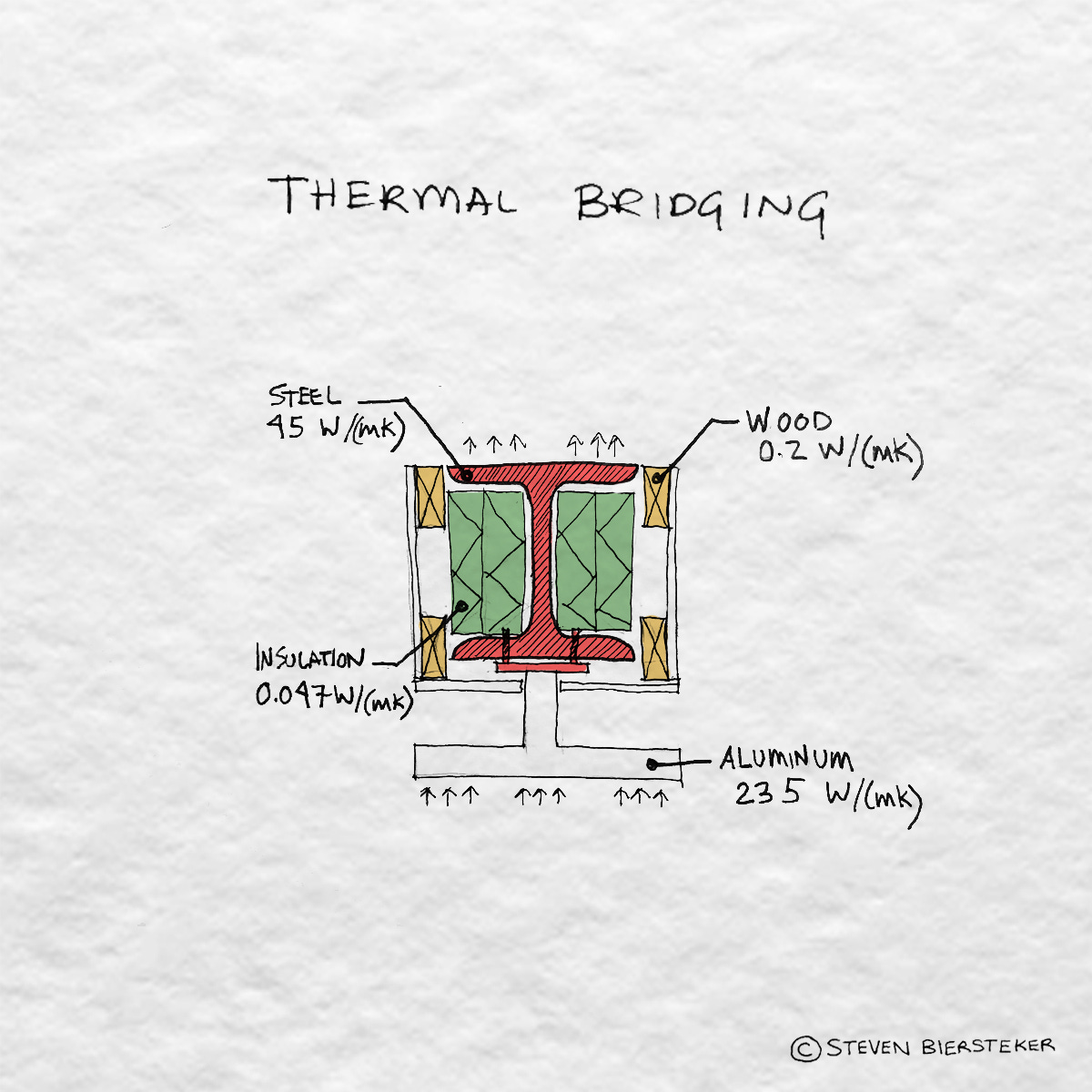

Thermal bridging is exactly how it sounds. It’s a bridge that takes energy in and out of a building at a quicker rate than the areas around it. Thermal bridging has different effects depending on the amount of material and the thermal conductivity of the material. For example, steel has a thermal conductance value of 45 W/(mk), wood on the other hand is 0.2 W/(mk), and aluminum is 235 W/(mk). Interestingly stainless steel has a conductivity of 14 W/(mk). So, heat moves faster through aluminum than steel, and faster through steel than wood.

If you don’t believe me I’d recommend doing a personal experiment (although I take no responsibility for you injuring yourself.

Step 1 - Boil a pot of water on the stove

Step 2 - Stick a piece of wood and aluminum in

Step 3 - Hold the wood in one hand and the aluminum in the other

Step 4 - Which one heats up first?

Now to really illustrate Thermal Bridging:

Step 5 - Wrap a towel around each hand.

We all know intuitively that wrapping a towel around your hand doesn’t do a whole lot to reduce the heat transfer from the water to your hand. That’s because the energy is running much faster through the wood and aluminum than through the towel. It’s strange because we do it all the time in buildings. Steel beams that penetrate the envelope, steel studs with insulation between them, and steel z-girts that extend through exterior insulation. It’s completely bizarre!

Next time you are stirring a pot of boiling water with an aluminum spoon, ask yourself why we do this on our buildings!?

In a future issue, we will get into more detail on how thermal bridging can be calculated in a building by understanding what a PSI factor is all about. For now, we’ll just focus on the basics.

THE GRAPHIC

WHY IT MATTERS

Thermal Bridging matters for three primary reasons:

Energy use

You are wasting your money on insulation

It is one of the biggest mold risks

Let’s dig a little deeper:

1 - Energy use

The most obvious answer is that thermal bridging is a massive source of energy loss in buildings. This is especially true as our buildings become more highly insulated and more efficient. You can continue to add insulation onto the outside, but if you don’t deal with those pesky thermal bridges you will be limiting the power of the additional benefit.

2 - You are wasting your money on insulation

Nobody likes to waste money, and that is what a thermal bridge represents in the envelope. First, every thermal bridge in your building limits the effectiveness of your insulation, and thus the money you paid for it. Insulating between metal studs can reduce the insulation value by up to 50% from the nominal value. Would you buy a car that only performed 50% as it was designed to? Neither would I.

Second, over the long thermal bridging sucks energy from the building and costs the owner and occupant money through energy costs. It’s often very affordable to reduce these bridges by simply adding a few materials, changing some materials, or revising the design.

3 - It is one of the biggest mold risks

Condensation is a killer for building envelopes, especially high-performance ones that tend to breathe less than their counterparts. Thermal bridges cause the temperature inside the wall to fall below the dew point and thus cause points of condensation within insulation layers. This can be a serious problem over the long term as moisture can go undetected and eventually result in mold and rot within your wall cavity. This is a serious failure you don’t want to deal with down the road.

1 TIP TO REDUCE

If you aren’t already, start by identifying and learning to improve your thermal bridging details. Some specific places to look are - balconies, window frames, foundation wall transitions, roof-to-wall connections, and roof overhangs. If you want somewhere to start looking - check out the resources below.

1 PERSON TO FOLLOW

Larry Clay is awesome. He is passionate about building high-quality and high-performance homes and the key - TELLING PEOPLE HOW TO DO THE SAME.

1 RESOURCE TO ACT ON

Have you heard of ThermalEnvelope.ca? It is an amazing resource to help you understand how different details perform specifically when it comes to their PSI value or thermal bridging impact. Each detail is simple to find and easy to understand. Here is a snippet from the catalog.

I wonder, and excuse me for my ignorance or just not being aware. Is it common in architecture in the USA to think about thermal bridges? I would think because you most commonly build in wooden structures this is less common? Please do correct me if I'm wrong. Perhaps this is a misconception of me.