CA57 - The end of curtainwall

Trumps climate action plan, curtainwall embodied carbon, sustainable bricks + more.

NEWSWORTHY

THE TOPIC

Should we build skyscrapers? Probably not, at least from a carbon perspective.

There are actually many reasons, but one of which is their skin.

Todays question:

Should we skin buildings in curtainwall and is there a better way?

You can probably guess that curtainwall isn’t great. Yet we continue to build, build, build with it.

Rather than guessing how bad it is, I want to dig deeper.

GIVE ME THE NUMBERS!

So I went digging and found some great resources from Ha/f Climate Design.

Honestly - if you need embodied carbon research, they are a great place to start looking.

Most of the numbers from todays issues come from their A Whole Life Carbon Approach to Building Envelope Design.Some were cross referenced with the Payette Kaleidoscope Tool.

Let’s dig into it.

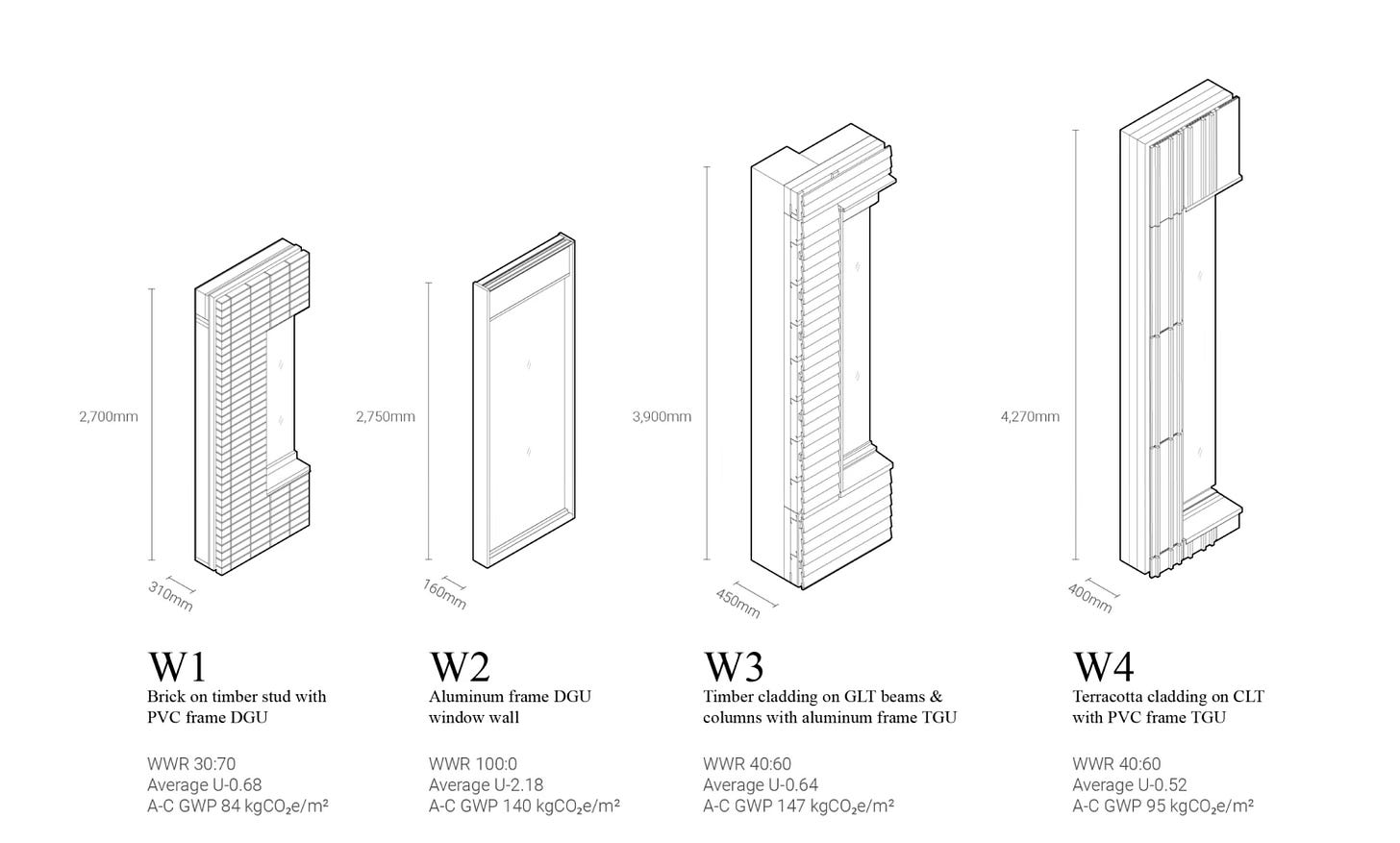

Ha/f Climate design took the approach of analyzing four different typical wall types.

We’ll just look at two.

Assumptions

Lifecycle Time = 60 years

Lifecycle Stages = A-C

Location = Toronto, Ontario

Operational Energy = 100% Electricity

W1 - Brick on Timber Stud w/ PVC Windows (Double Glazing)

Window to Wall Ratio = 30%

U Value = 0.68 R Value = 8.35 (Imperial)

Embodied Carbon (A-C) = 85 kg/m2

Operational Carbon = 18.77 kg/m2

Whole Life Carbon = 207 tCo2e

Split = 18% Operational | 82% Embodied

W2 - Aluminum Curtainwall (Double Glazing)

Window to Wall Ratio = 100%

U Value = 2.18 R Value = 2.60 (Imperial)

Embodied Carbon = 140kg/m2

Operational Carbon = 60.70kg/m2

Whole Life Carbon = 4014 tCo2e

Split = 30% Operational | 70% Embodied

Using the Kaleidoscope tool is a bit of a different approach.

Making all walls equal at an R 15.675 and analyzing their carbon impact.

Here are two walls that tell a similar story:

Curtainwall w/ Aluminum backpan & 5.5” Insulation

Embodied Carbon (A-C) = 237kg/m2

Embodied Carbon (A-D) = 161 kg/m2

Rainscreen w/ thin brick cladding

Embodied Carbon (A-C) = 96 kg/m2

Embodied Carbon (A-D) = 58 kg/m2

So what does all this mean?

Well I think there are a few things to consider here that should affect they way you design buildings.

Aluminum curtainwall systems have the worst thermal performance of most wall systems and the highest embodied carbon of most wall systems.

We SHOULD NOT be wrapping our buildings in curtainwall.

Its terrible for performance, it’s terrible for embodied carbon.

Period.

Yes, there are some factors like recyclability that are not truly factored into this analysis, but that aint no reason to wrap the world in aluminum.

Using the Kaleidoscope approach of equalizing the R-Value of the system (although I’m not sure you could build a standard curtainwall to meet R15) you see a 147% increase in embodied carbon to move from a traditional wall to curtainwall. Now keep in-mind this is only for the opaque part of the wall (the spandrel) it doesn’t factor in the addtional poor performance of the actual window itself. Even when we include module D the curtainwall is actually a larger impact at 177% increase.

Looking at the Ha/f Climate Design approach of looking at the entire wall system you see a 68% decrease in insulation performance. Two things to factor in here. The W1 wall system has a much smaller glazing area (30% compared to 100%) and it’s window is vinyl. When we look at embodied carbon the increase of the curtainwall system is 65%.

This is where the rubber meets the road. When we look at the operational carbon intensity of the Ha/f Climate Design walls we see a 223% increase in operational carbon. This factors in both the operational efficiencies lost, and the size of glazing. Keep in-mind this is also in an area with a pretty clean electrical grid! Imagine what a dirty grid would look like.

In conclusion - I think it’s pretty obvious that building skyscrapers with ground to roof curtainwall is not a solution for the future. It may be cheap and easy to construct, but it aint the way to the future IMHO.

THE PERSON

Rachael Owens is the Head of Sustainability at Buckley Gray Yeoman and a member of the Architects Climate Action Network, where she coordinates the Climate Literacy group. She is a champion of adaptive reuse and has a wealth of experience working with existing buildings. In 2021 I she was named a RIBA Journal Rising Star for her work in practice to communicate sustainable design and within ACAN to campaign for the regulation of embodied carbon emissions. Give her a follow!

THE MATERIAL

The K-BRIQ® is a premium brick product combining a competitive technical specification with superior sustainability and an ultra low carbon performance. Every K-BRIQ® tells a story. Made using compression technology from near 100% recycled construction and demolition waste, it retains its own character and offers an elegant solution and versatility as an architectural façade or interior surface material.